Blackalloy™ Self-Feeding Drill

Motor Options for Self-Feeding Drill

The Blackalloy™ Self-Feeding Drill can be equipped with an electric (or air) motor to power rotation of the spindle. It can be configured with a timing belt and pulleys to increase/reduce the RPMs output at the spindle. It can be configured with a sealed hydraulic feed control and stop bracket (as shown). By adjusting the stop bracket, which mounts on a common surface with the drill unit, you can engage the feed control just before contacting the workpiece, allowing the drill unit to stroke rapidly to the workpiece then travel through the workpiece at an adjustable, controlled feed rate.

The length of stroke can be reduced using the yellow zinc adjustment nut so that the length of stroke can be optimized to the depth of cut. With the optional pneumatic controls kit, once the stroke completes, the pneumatic limit switch activates the return stroke and the drill unit retracts from the workpiece, returning to the original starting position, ready for the next cycle.

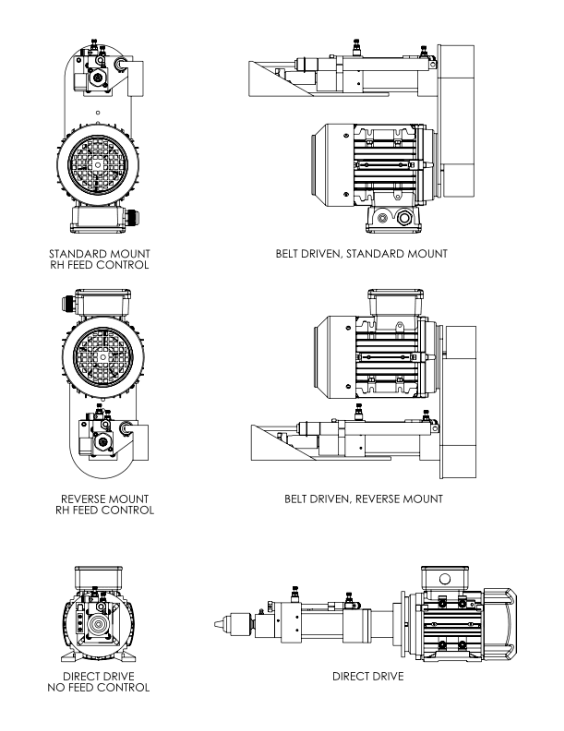

Mounting Options For Self-Feeding Drill

There are a number of mounting options available for the self-feeding drill relative to the position of the motor. Belt driven configurations are available in a standard mount, a reverse mount, or motor plates can be custom made with the motor rotated 30°, 60°, & 90° from the orientations shown. (See Image)

If you prefer, the drill unit can be configured with a direct drive electric (or air) motor mounted and coupled in-line with the drill unit spindle. This drives the spindle at the same rate as the motor. In this configuration, you would need to configure the unit with a Variable Frequency Drive (VFD) to vary the RPMs at the spindle by varying the motor RPMs. This configuration comes with a caveat. Deviating from the nominal RPMs using a VFD reduces the amount of available torque output by the motor. The farther you deviate from the nominal RPMs, the greater the loss of torque.

Thrust Capabilities for Self-Feeding Drill

The model 150/250 series self-feeding drill units are capable of producing thrusts of up to 182 lbs. with 100 PSI air pressure and 364 lbs. with 200 PSI oil pressure. The model 350 series self-feeding drill units are capable of producing thrusts of up to 420 lbs. with 100 PSI air pressure and 630 lbs. with 150 PSI oil pressure. These units are usually used for drilling, reaming, boring and light milling applications, but can also be used whenever simultaneous rotary and linear motions are required. It can be mounted in any position, horizontal, vertical etc.

The thrust capacity of the drill unit is important when determining whether the drill unit will be capable of drilling the desired hole size in a given material. An optimal amount of thrust, usually expressed in pounds of force, is required to remove metal. If the thrust is not sufficient to allow the drill to cut through the material, the drill will spin on top of the material creating friction, heating the drill and the workpiece, leading to dulling the drill and work hardening the material, making it more difficult to cut.

Some allowances can be made based on the cutting tool used. For example, using a split point drill can reduce the thrust required by approximately 40%. This is often the reason a maximum hole diameter is listed in the drill unit specifications based on the material being drilled.

Additional Options for Self-Feeding Drill

Our modular approach gives users the option of selecting only those components which are required for specialized drilling applications. Additional drill unit components and attachments are available to complete your drill unit, including a range of key type chucks, ER style collet chucks, self-reversing tapping heads by Tapmatic, multiple spindle drilling heads, pneumatic controls, etc.